There’s a multitude of methods for welding used to melt and fuse different kinds of metals and substances. The form of assignment you’re working on, along with the components that are being fused, influences the technique that is selected. Gas welding is one of the earliest forms of heat-based welding, which is used in an array of industries including metallurgy, shipbuilding, and automotive. It has replaced traditional stick welding as the preferred technique for business or domestic welding.

[Image source: https://commons.wikimedia.org/]

Interesting Science Videos

What is Gas Welding?

Gas welding, commonly referred to as oxy-fuel welding, uses heat produced by lighting a mixture of gases to melt and fuse metal. The blaze generated during gas welding is produced by just lighting a mixture of gases.

It is also known as the oxy-fuel process. Oxygen and acetylene are considered to be the major gas combinations since they are the most effective at producing heat to weld steel, which is why the process is known as oxy-fuel or oxy-acetylene welding. At a temperature of roughly 3500°C, an oxygen-acetylene mixture combusts, resulting in flame. When the engaged fire comes into contact with the workpieces, it softens the surface, creating a liquid pool that allows welding to take place. Other fuel gases utilized in the process include propane, hydrogen, and coal gas. It is also one of the most common methods of welding.

Types of Gas Welding

There are different types of gas welding in this section we will be discussing it briefly. Let’s look at some of the important types of gas welding.

MIG Welding

- MIG or (Metal inert gas) is the welding process that involves shielding gases that are inert, such as argon and helium. This method of welding is applied to aluminum alongside other nonferrous metals.

- The gas acts as a shield and prevents oxygen in the air from accessing the welding region. The chemical composition of the shielding mask has an immense effect on the process of welding.

- An electric arc is formed between the metal and the consumable electrodes. Electrodes are constantly fed into the weld pool.

- This gas has the potential to alter arc stability, metal transfer, and spark spatter. It may even influence the mechanical characteristics of the welded junction.

TIG Welding

- Tungsten Inert Gas (or TIG) also referred to as Gas tungsten arc welding, is a type of arc welding.

- This is similar to the MIG welding that we have already discussed above.

- However, welding with TIG eliminates the need for frequent electrode replacement because its tungsten is non-consumable, as opposed to MIG welding.

- TIG welding gives a high-quality finish with better results with minimal smoke and fumes.

- The inert shielding gas serves to keep oxides and other chemical compounds from forming in the weld, which might weaken the weld and make it less resistant to corrosion.

MAG Welding

- MAG welding or metal/active gas welding is another form of arc welding that is similar to MIG welding, however, it uses different shielding gases.

- Using the active combination of active gases, it creates an effective shielding gas that is helpful for steel welding. These gases are typically a combination of oxygen, CO2, and argon.

- The arc becomes more conductive with the use of active gases increasing the voltage of electricity leading to the temperature rise at the weld pool.

- The rise in temperature helps to get deeper penetration making it useful in the welding of thicker material.

Oxy-Acetylene Welding

- The most widely employed gas welding technique involves oxy-acetylene welding.

- Acetylene and oxygen gases are combined to supply the welding flame in oxy-acetylene welding.

- Among the different fuel gases, acetylene is often the most costly; nonetheless, this gas mixture offers the maximum flame temperature.

- This process works with a variety of ferrous and non-ferrous metals, but it is most typically employed with copper, brass, and bronze.

- Since it is an unstable gas, acetylene needs to be handled and stored carefully.

[Image source: https://fractory.com/gas-welding-explained/]

Oxy-Gas Welding

- Oxy-gas welding is a kind of gas welding where a fuel gas is burned along with oxygen.

- In oxy-gasoline welding processes, compressed gasoline is used as welding fuel in locations where acetylene cylinders are scarce.

- Gasoline torches have proven to be more effective in welding thick plates compared to acetylene.

- Gasoline is sometimes hand-pumped through an inflation cylinder, an everyday practice among jewelry makers in poor places.

Hydrogen Welding

- This is a variation of gas welding which replaces acetylene with hydrogen as a flammable gas.

- Hydrogen is capable of being operated at greater pressures compared to other fuel gases, which makes it ideal for underwater welding tasks.

- It has been displaced by other welding techniques (such as arc welding) in some of these applications, although it still has a niche market.

- This type of method is commonly used in the jewelry market and also to produce laboratory glasses.

Propane – Butane Gas Welding

- Propane (together with butane in combinations) is usually referred to as Liquified Petroleum Gas.

- Butane and propane are related gases that can be utilized as fuels separately or in combination.

- When butane and propane are combined with oxygen they create a flame in a torch which has a lower temperature compared to acetylene.

- This gas cannot be used for welding as it creates an oxidizing environment leading to rust.

- They are usually employed for brazing, cutting, and soldering.

- They are cheaper and lighter which makes them easier to carry around.

- It requires different torch tips as it is heavier gas.

MAPP Welding

- MAPP (Methylacetylene-propadiene-petroleum) is a mixture of gases that are inert compared to other.

- In order to weld, braze, and solder, original MAPP gases are mixed with oxygen. Following this process, the flames go as hot as 2900 °C.

- As it is a safer gas to store at room temperature, amateurs and recreational welders can use it with greater safety.

- High-volume cutting processes can employ MAPP since it can operate at extremely high pressures.

Air-Acetylene Welding

- Air-acetylene welding requires the burning of acetylene gas combined with air. This results in a reduced heat output compared oxy-acetylene welding.

- As a result, the approach is preferred for soldering pipes in HVAC systems, as the lower heat input helps to prevent the solder and flux from overheating.

- Unlike oxy-acetylene welding, which requires a second cylinder for the oxygen, acetylene welding requires only one gas in a pressurized cylinder.

Essential Equipment For Gas Welding

To perform the gas welding we need to get some essential tools. Without these tools gas welding is not possible. Let’s have a brief look about the essential equipment’s for gas welding.

Oxygen Cylinder

- A steady supply of pure oxygen is a vital component of a gas welding system.

- The oxygen cylinder contains the compressed oxygen necessary for the welding.

- Both the oxygen and fuel cylinders are built to withstand the pressures of their respective gases.

- These cylinders are typically painted black, though this may not always be true.

Fuel Cylinder

- The fuel gas is unquestionably among the most significant components of a gas welding system.

- It is normally kept in a cylinder of a particular kind.

- The cylinder is tightly sealed and constructed of heavy-gauge steel to avoid pressurized gasoline from damaging it.

- These cylinders are commonly painted Maroon but it might not always be the case.

Pressure Regulator

- Since both the fuel and oxygen gasses are held under high pressure, some way of lowering the amount of pressure is necessary for secure operation throughout the welding process.

- This is the time when a pressure regulator comes in quite handy.

- This tool often assists in delivering oxygen at a consistent pressure of 70 to 130 kN/M2 and fuel at 7 to 103 kN/M2.

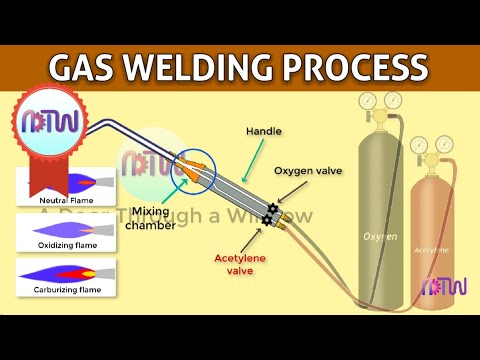

Valves

- Each of the gases require independent control valves.

- A valve that can be controlled is an instrument to regulate the quantity of gas emitted from the gas cylinder.

- These valves additionally play important role in regulating the fuel-to-oxygen ratio.

Mixing Chamber

- Mixing chamber is another important part required for the gas welding.

- This chamber basically help the mixing of fuel and oxidant safely.

- To ensure the correct flow and maintain the proper flow of gases in the chamber control valves are helpful.

Hoses or Pipes

- To put it simply, they’re pipelines engineered to let different gases pass through it without reacting.

- Each gas welding machine typically comes with two hoses: one for oxygen and the other for fuel gas.

Flashback Arresters

- The oxygen and fuel gas hoses are linked with the welding torch and gas containers, with the gases flowing via flashback arresters and pressure regulators.

- Flashback arresters are security features which inhibit a flame from returning into the gas cylinders in an instance of a backfire.

Torch

- This is the final stage of gas welding, and it involves the use of a welding torch.

- The torch is an opening that ignites the fuel-oxygen combination for simplicity of use by the operator.

- The torch features a screw-in nozzle from a set of nozzles with varying diameter holes that provide the appropriate flames size resulting in the necessary heat for the metal and thickness that needs to be welded.

Protective Gears

- Even though the protective gear is not an essential part of gas welding.

- The operator needs to put on protective clothes as well as tinted goggles when welding.

- General-purpose colored goggles can work perfectly considering the less powerful flame and little to no emission of UV.

Process of Gas Welding

- Gas welding is performed using a flame created by burning nearly equal amounts of oxygen and acetylene, which are supplied at equivalent pressures through gas cylinders to a welding torch.

- The temperature of flame is approximately 3500 °C, which is comfortable enough to melt the steel and other metals.

- Filler metal can be added by manually placing a rod in the outer border of the weld pool simultaneously moving the torch along the joint. The pool then cools and the parts fuse together, forming a solid connection. The welder’s flame should be moved gently in order for the joint to cool down avoiding oxidation, which might result in fragile connections.

- Fluxes are used for the purpose of cleaning and safeguarding other kinds of metal from oxidizing while welding, which include stainless steel, cast-iron, aluminum-based alloys, and copper alloys.

Things to Remember During Gas Welding Procedure

While performing the gas welding certain parameters can change the desired outcome. There are some major points to be taken into the account while going through the process of gas welding in order to achieve the best possible outcomes. We are going to take a brief look at these key points.

Pressure

- Pressure of the gas during the procedure plays an important role in the final result.

- When the pressure ratio between the oxygen and fuel is adjusted using the control valves, variation in the flames can be achieved.

- Three different types of flames can be produced; neutral, oxidizing, and carburizing which will be discussed below in details.

- These different flames should be maintained depending on the types of metal you are working. Slight adjustment of the flames which hugely impact the outcome.

Temperature

- Another crucial factor to consider is the temperature of the flame.

- The used ratio of the oxygen and fuel is what determines the temperature of the flame.

- Increase in the fuel causes the temperature to go lower, whereas lowering the fuel flow will cause the temperature to rise higher.

- Depending on the melting point of the metals or materials being used the temperature must be adjusted.

Movement Speed

- Operators speed is another factor that dictates the outcome of the gas welding.

- The level of speed used during the weld impacts how long it takes to efficiently form a weld pool.

- Welder should be smooth with the timing of movement cause the fast movement can lead to the incomplete weld, whereas slow movement can create a hole through the metal.

Torch Position

- Position and angles of the torch firing during the gas welding effects the final result.

- Feeding rate of the filler and the position of torch determines the weld pool size welder gets.

- Larger weld pool might suggest that it is overheated in such cases welder must change the torch position parallel to the weld so that heat can be deflected.

- Similarly, smaller pool indicates low heat which requires the operator to hold the torch in perpendicular position foe metal to get it hotter and form weld pool.

Types of Gas Welding Flames

The variety of welding flames produced has a significant impact on the final weld connection and its qualities. The flame’s appearance is altered by changing the fuel gas and oxygen flow rates.

Higher levels of oxygen produce a hotter flame, which may cause the metal to distort. A cooler flame develops when there is greater concentration of fuel gas present compared to oxygen, which may result in poor weld quality. There are three different types of flames which are discussed briefly here:

Neutral Flame

- When the equally measured volume of oxygen and acetylene are passed through the hose and ignited it results in neutral flame.

- This flame helps to maintain the properties of weld metal and produces the minimal of the smoke.

- This type of flame has two cores; outer one being the blue color and inner one with the white color.

- Inner core produces the heat of upto 3100 °C meanwhile outer zone has the approximate temperature of about 1275 °C.

- Its applications include welding stainless steel, copper, cast iron, aluminum, and mild steel.

Oxidizing Flame

- When the volume of oxygen passing through the hose is greater compared to the fuel gas it ignites producing the oxidizing flame.

- Temperature rises at higher possible point in this type of flame producing the sound that is similar to the roar.

- This type of flame also has two cores; outer one being the blue color and inner one with the white color similar to the neutral flame.

- However, Inner core produces the heat of upto 3500 °C meanwhile outer zone has the approximate temperature of about 1275 °C.

- It is applied to weld alloys such as brass and iron carbide, as well as braze ferrous metals.

Carburizing Flame

- When the volume of fuel gas passing through the hose is greater compared to the oxygen it ignites producing the carburizing flame.

- The flame produced is hazy and silent, forming metal carbide through chemical reactions.

- This flame produces three different layers; white inner zone, red intermediate zone, and the blue outer zone.

- These three different layers has a different temperature levels; inner core being 2900 °C, intermediate zone with 2500 °C and the outermost zone with 1250 °C.

- It is used for welding high carbon steel (HCS) and cast iron.

Importance of Gas In Welding

There are different ways to weld the materials however the gas welding is one of the most popular way of welding. Uses of Gas in welding has some advantages over other methods. Here we will look at some of the benefits of gas welding.

Shielding

- The word ‘shielding’, have been mentioned multiple times above.

- Shield is a protective barrier comparable to the gas dome. This shield creates a dome like gas barrier over the weld pool, at the fusion point of metals.

- Shielding gases can be provided externally or produced by the burning of an electrode’s coating, which is a feature found in certain welding procedures.

- Shielding gas are supplied using the electrodes coating.

- Its major function is to safeguard the welding joint from pollutants, limiting contact with chemical reactions or environmental elements including oxygen, nitrogen, water vapor, and other impurities that might compromise and impair the weld.

- Argon, helium, and carbon-dioxide are some of the common shield gases. However CO2 is commonly used as it is cheaper solution.

Purging or Inerting

- Purging is the process of purification; however in the case of gas welding it is the process of removing the contamination that can impact the outcome.

- Similar to shielding gases, purging gases are applied below the weld joint as opposed to above it.

- Purging gas is used at the initial stage of gas welding to maintain the contamination free environment while sealing the joints.

- Nitrogen, and carbon-dioxide are most commonly used purging gas although helium, and argon can also be employed.

Blanketing

- Blanketing in the welding is the protective layer of gas that helps to protect the metal joint once the process of welding is completed.

- Shielding might not be enough for the protection of welded material since the high heat produced in the process of welding makes the joint vulnerable to unwanted reactions with the environment.

- Blanketing gases helps to maintain the physical properties of the metal welded.

- Nitrogen is the most commonly used gas for blanketing as it is cheaper and readily available.

Heating

- Heating is the process of creating the weld pool by increasing the electric voltage in the welding arc.

- If joints cool of rapidly it can lead to the cracks, in order to slower the cooling process and preserve the structural integrity of welded material heating gas plays an important role.

- Heating gases are used to weld steels where cold cracks can be problamatic.

- Carbon-dioxide and argon are the heating gases used; although they are inert but can be reactive when the temperature rises.

Applications of Gas Welding

Gas welding offers a range of application and it has been used for a long time in commercial and household purposes. Some of the major application of this method are discussed here:

Repair and Fabrication

- Sheet metal components like cabinets, enclosures, and structural pieces are made using gas welding. It is used to repair metal structures, machines, and gear so that their integrity and usefulness can be restored. By joining incompatible metals, these procedures allow for the creation of composite structures and the refurbishment of parts with various metal compositions.

Automobile Industry

- Automobile bodywork, frames, and exhaust pipes can all be fixed by gas welding. Since it offers you the ability to regulate the heat input, it’s the preferred option for fragile repairs. Gas welding ensures leak-free connections and the ability to withstand extreme temperatures and vibrations, which is why exhaust systems are typically constructed using this technology. Gas welding techniques are used in the manufacture of fuel tanks for automobiles to ensure solid and solid connections.

Aircraft Industry

- Gas welding serves a purpose in the fabrication and maintenance of aircraft frameworks, such as fuselage sections and wing components, to ensure durable yet lightweight welds. These techniques are used in the manufacture of fuel tanks for aircraft to ensure solid and solid connections.

Plumbing and HVAC

- Gas welding is commonly used in the welding and fabrication of pipelines across an array of businesses. It provides benefits including precise control and flexibility in connecting multiple kinds of pipework. It is a way to join copper pipes in plumbing and HVAC systems, providing long-lasting and free of leaks joints. It used in the building and maintenance of oil and gas pipelines to ensure dependable and durable welds that can endure extreme operating conditions.

Furniture Industry

- This technique is easy to use and cheaper in comparison this is used by the metal furniture industry. Accuracy and the durability of the joints made by this method helps to make a standard framework for furniture. This process is commonly utilized to create custom metal furniture, such as tables, chairs, and decorative metalwork.

Sculpting

- Gas welding allows architects and craftsmen to create detailed and distinctive creations with metals as the material of choice. This method provides the high level of accuracy and control required for the complex designs. It allows artists to flawlessly combine metal components, resulting in sculptures with complicated shapes and designs.

Jewelry Industry

- This method provides the high level of accuracy and control required for the complex designs. It is used to resize rings and repair broken jewelry, leading to flawless and permanent joins. It also allows jewelry designers to create unique items by precisely mixing multiple metals and elaborate designs.

Advantages of Gas Welding

- One of the biggest advantage of working with the gas welding is its ability to weld the ferrous metals with non-ferrous metal, or it can weld the metals and non-metals together which is unque in itself.

- Unlike most other types of welding, gas welding does not require electricity to operate. In contrast with arc welding, the gas-based welding materials is capable of working without electrical connection. This makes it applicable in rural areas without electric connection or in the areas where blackout is common occurrence.

- This does not require any heavy-duty or specialized apparatus which excludes requirement for a highly skilled operator to operate and setup this equipment. This setup can be purchased even for a household purpose as it has the minimal initial cost compared to other welding machines.

- It is one of the basic method of welding which makes it easier for the beginners to work with. It is also one of the readily available set up which can be helpful for anyone to learn and get into the business.

- It is portable and can be carried to the locations with ease. This makes it useful in remote places.

Disadvantages of Gas Welding

Gas welding has its share of disadvantages as do other methods. Here are some of the major disadvantages of gas welding.

- The heating pace is slow, therefore the complete operation takes longer. It is simpler than other methods of welding, but it also takes more patience.

- It does not achieve temperatures comparable to arc welding. As a result, it is not the most suitable welding method for high-strength steels.

- Titanium, zirconium, and high-speed steel (HSS) are not suitable to work with gas welding.

- This technique is be helpful with medium and thinner sheets; however thick sheets and heavy metal works cannot be done by gas welding which makes its application limited.

- The larger joint surface area gets effected by the constant heat.

- It lacks a specific flux shielding mechanism,

Video Reference

References

- https://www.sciencedirect.com/topics/engineering/gas-welding

- https://www.linkedin.com/pulse/welding-gas-types-applications-randall-stremmel-zfaec

- https://proleantech.com/gas-welding-a-comprehensive-guide/

- https://www.dnhsecheron.com/blogs/guidelines-to-understand-gas-welding-applications-advantages-disadvantages

- https://www.uti.edu/blog/welding/gas-welding

- https://www.adamsgas.co.uk/2022/02/10/types-of-welding-gas-and-what-theyre-used-for/

- https://www.twi-global.com/technical-knowledge/job-knowledge/oxy-fuel-welding-003

- https://fractory.com/gas-welding-explained/

- https://www.xometry.com/resources/sheet/what-is-gas-welding/#:~:text=Gas%20welding%20is%20a%20process,when%20they%20think%20of%20welding.

- https://testbook.com/mechanical-engineering/gas-welding-process-types-and-applications